Smart maintenance

starts

with

smart sensor

data collection.

Smart maintenance of your

critical assets starts with collecting the right sensor data.

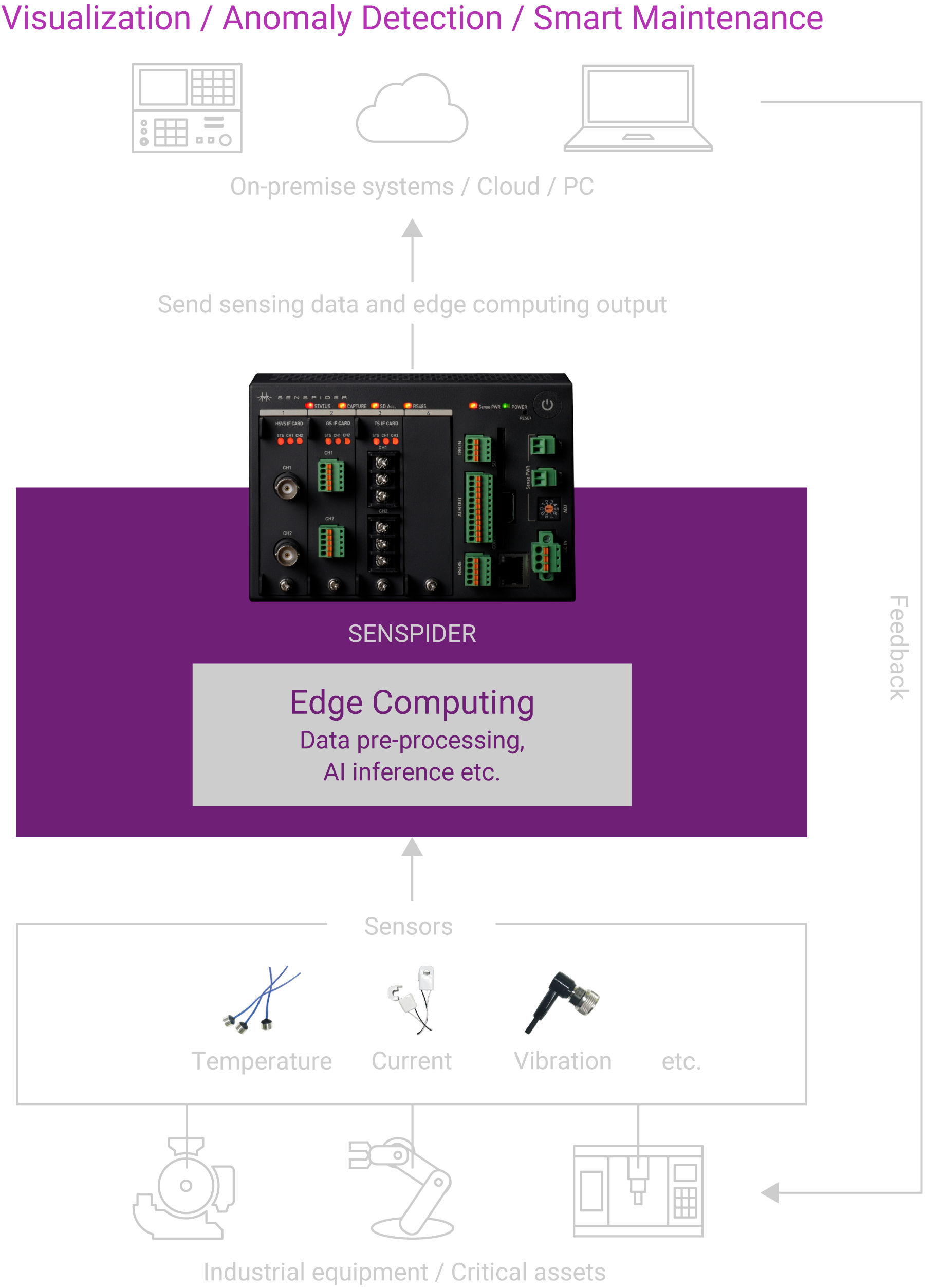

With SENSPIDER, our edge computing solution, you can collect various types of sensor data simultaneously and

build AI-powered Condition-based Maintenance (CBM) preventing sudden machine outage and downtime.

SOLUTION

Smart Sensor Gateway

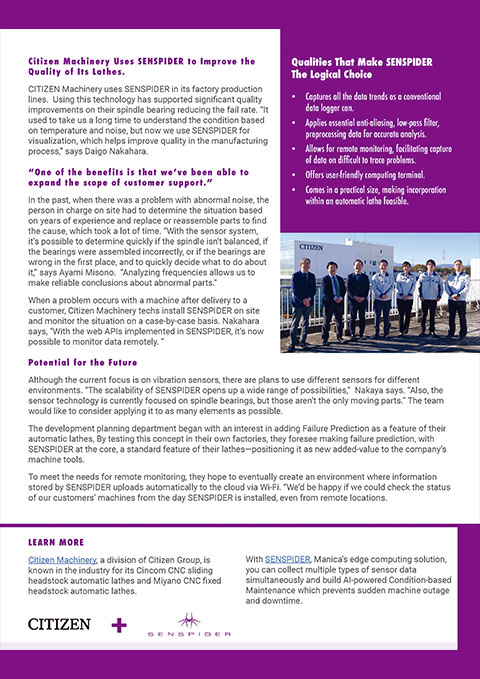

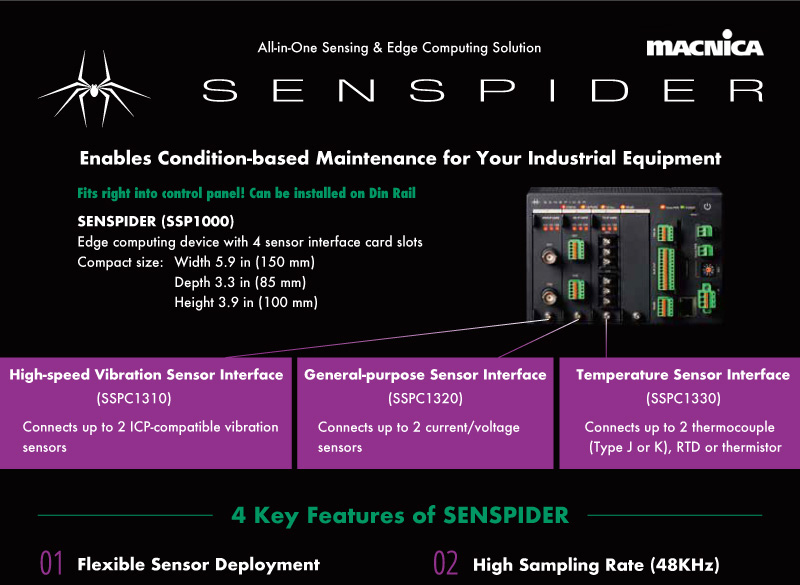

Vibration sensors are commonly used to inspect rotating equipment within critical assets as the failure of such equipment appear as changes or increases in vibration. In order to implement effective CBM, it is necessary to obtain vibration data at high sampling rate, and to perform pre-processing, status check, and AI inference at the edge. SENSPIDER is designed to solve all of these challenges.

01

02

03

WHY SENSPIDER

SENSPIDER focuses on helping customers to solve their challenge in smart maintenance and has been trusted by many manufacturing companies.

Simple, low cost deployment model

When using data logger or PLC to collect sensing data, it usually requires a dedicated I/O slot per sensor type, external amplifier, power supply, and ladder development, ending up in a complex and costly deployment. SENSPIDER covers all of these in one box, and also supports edge computing.

Flexible Edge AI Platform

Users can implement pre-processing of sensing data and custom AI models on the edge.

Trusted by leading manufacturers

SENSPIDER has been adopted by a broad range of manufacturing companies including major industrial equipment manufacturers for their CBM projects.

HOW IT WORKS

By leveraging edge computing capabilities on SENSPIDER, you can build a PC-less smart maintenance system. From data pre-processing to custom AI model inference, SENSPIDER covers many edge computing use cases based on open technologies.

CASE STUDY

CUSTOMERS

SENSPIDER

SENSPIDER datasheet with hardware spec and more.

SENSPIDER × Sigma

Collect rich sensor data and build a CBM system with no code using smart sensor gateway SENSPIDER.

Practical First Steps Toward Predictive Maintenance

Step-by-step guide for machinery manufacturers to implement predictive maintenance using sensor data.